Need an Estimate? Drop a note below and a qualified technician will contact you shortly.

TRANSMISSION SERVICE & REPAIR

We provide transmission service and repair at a reasonable cost!

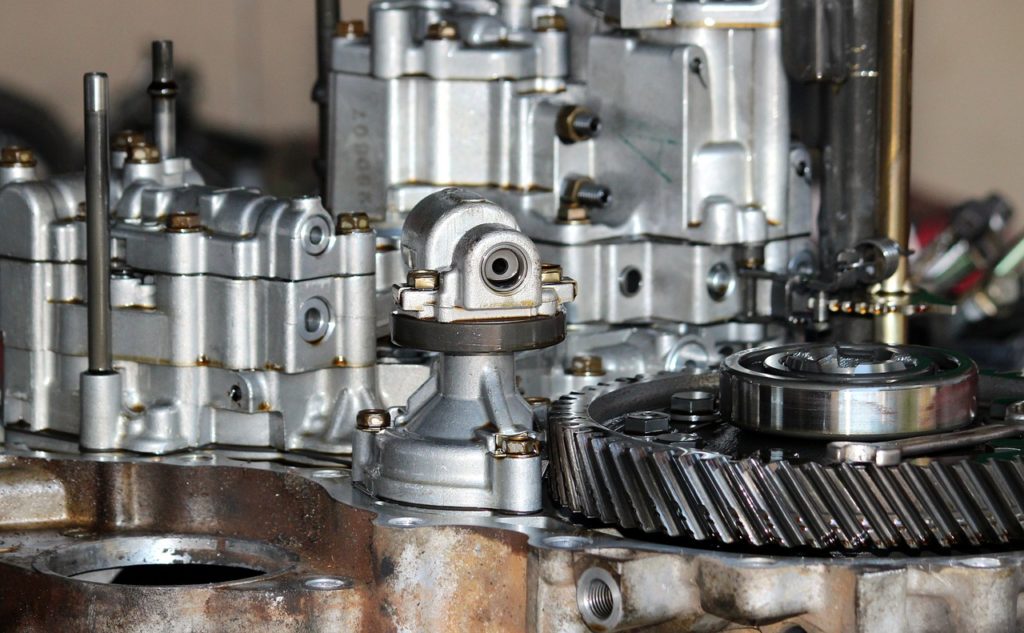

Simply put, your transmission is a system of gears and/or hydraulics that transfers the mechanical power from your engine to the other moving parts of your car where it needs to be.

Yeah, it’s complicated, that’s why you need a good mechanic like Vandelay Motors for all of your repair needs!

How often should you service your transmission?

Transmission fluid is a liquid that lubricates the moving parts inside your transmission. In automatics, this fluid is also a coolant and transmits power from the engine to the transmission.

Different fluids are required for different types of transmissions. You could get out your owner’s manual and see what type of fluid your vehicles requires, or just trust a friendly mechanic at Vandelay Motors.

MANUAL TRANSMISSIONS:

Typically, most manufacturers suggest that the transmission fluid be changed every 30,000 -60,000 miles. Some heavy usage situations may require this more often, just check with your Vandelay mechanic.

AUTOMATIC TRANSMISSIONS:

Cars with Automatic transmissions vary quite a bit. Typical service range is 60,000 – 100,000 miles. Of course, you can change it more often to be on the safe side, that won’t hurt.

Auto Repair 101: Learn More About

Transmission Service & Repair

according to Wikipedia:

A transmission is a machine in a power transmission system, which provides controlled application of the power. Often the term 5 speed transmission refers simply to the gearbox that uses gears and gear trains to provide speed and torque conversions from a rotating power source to another device.[1][2]

In British English, the term transmission refers to the whole drivetrain, including clutch, gearbox, prop shaft (for rear-wheel drive), differential, and final drive shafts. In American English, however, the term refers more specifically to the gearbox alone, and detailed usage differs.[note 1]

The most common use is in motor vehicles, where the transmission adapts the output of the internal combustion engine to the drive wheels. Such engines need to operate at a relatively high rotational speed, which is inappropriate for starting, stopping, and slower travel. The transmission reduces the higher engine speed to the slower wheel speed, increasing torque in the process. Transmissions are also used on pedal bicycles, fixed machines, and where different rotational speeds and torques are adapted.

Often, a transmission has multiple gear ratios (or simply “gears”) with the ability to switch between them as speed varies. This switching may be done manually (by the operator) or automatically. Directional (forward and reverse) control may also be provided. Single-ratio transmissions also exist, which simply change the speed and torque (and sometimes direction) of motor output.

In motor vehicles, the transmission generally is connected to the engine crankshaft via a flywheel or clutch or fluid coupling, partly because internal combustion engines cannot run below a particular speed. The output of the transmission is transmitted via the driveshaft to one or more differentials, which drives the wheels. While a differential may also provide gear reduction, its primary purpose is to permit the wheels at either end of an axle to rotate at different speeds (essential to avoid wheel slippage on turns) as it changes the direction of rotation.

Conventional gear/belt transmissions are not the only mechanism for speed/torque adaptation. Alternative mechanisms include torque converters and power transformation (e.g. diesel-electric transmission and hydraulic drive system). Hybrid configurations also exist. Automatic transmissions use a valve body to shift gears using fluid pressures in response to speed and throttle input.